In today’s world, where energy efficiency and sustainability are becoming increasingly important, Heat Recovery System has become a valuable solution for businesses and homeowners alike. By harnessing the heat generated from various processes, these systems can help reduce energy consumption and lower utility costs. This comprehensive guide will explore the benefits of heat-recovery systems, the different types available, and how they can be integrated into existing infrastructure to maximise efficiency.

The Environmental and Economic Benefits of Heat Recovery Unit

Heat Recovery Unit is a pivotal component in pursuing environmental sustainability and economic efficiency. By capturing waste heat that would otherwise dissipate into the environment, these systems significantly reduce the demand for primary energy sources. This process contributes to decreasing greenhouse gas emissions and plays a vital role in the battle against climate change. The strain on natural resources is lessened through the reuse of heat, exemplifying a commitment to eco-friendly practices.

Economically, the adoption of heat-recovery systems presents substantial savings on energy expenses. Organisations and households implementing these systems benefit from a marked reduction in utility bills. This is particularly relevant in the context of rising energy prices and the growing financial burden on energy consumers. The financial advantages extend beyond immediate bill savings, encompassing long-term economic benefits such as increased equipment lifespan. Heat-recovery technology reduces wear and tear by easing the demand for heating and cooling systems, thereby delaying the need for costly replacements and repairs.

The integration of heat-recovery systems also has a broader economic impact. It encourages innovation in energy-efficient technologies and fosters a market for sustainable solutions. This not only stimulates economic growth in the green technology sector but also supports job creation in industries related to energy efficiency. As such, heat-recovery systems’ environmental and economic benefits underscore their importance in the current and future landscapes of energy management.

Different Types of Heat-Recovery Systems and Their Applications

Different Types of Heat-Recovery Systems and Their Applications

Heat-recovery systems are categorised based on their functionality, the source of waste heat they utilise, and the methods by which they transfer heat. These systems are versatile and adaptable to various settings, from industrial facilities to residential homes. Here are some of the primary types of heat-recovery systems and their applications:

Heat Recovery Ventilation (HRV)

HRV systems are commonly used in residential and office buildings to improve indoor air quality whilst conserving energy. They work by extracting stale indoor air and bringing in fresh outdoor air, transferring heat between the two air streams without mixing them.

Thermal Wheel (Rotary Heat Exchanger)

Utilised predominantly in commercial and industrial settings, thermal wheels recover heat from exhaust air and transfer it to incoming fresh air. The rotating wheel, made of a heat-absorbing material, facilitates efficient heat exchange and is particularly effective in environments with high air volumes.

Run-around Coil Systems

These systems involve using two coils connected by a pipe to circulate a heat transfer fluid, which can be water or a glycol solution. Commonly found in buildings where supply and exhaust airflows are separated, run-around coil systems effectively recover heat from one air stream to preheat or cool another.

Plate Heat Exchangers

Suitable for residential and industrial applications, plate heat exchangers recover heat from exhaust gases and transfer it to a more relaxed fluid or air stream. Their compact design and high heat transfer efficiency make them ideal for space-constrained environments.

Heat Pumps

As a versatile tool for heat recovery, heat pumps extract heat from one location and transfer it to another. They can be used in various settings, including homes, commercial buildings, and industrial processes, to provide heating, cooling, or hot water.

Each type of heat-recovery system offers unique advantages and is suited to specific applications, contributing to energy savings and environmental sustainability. The choice of system depends on factors such as the scale of the application, available space, and the desired efficiency outcomes.

How Heat Recovery Exchanger Contribute To Sustainable Development

Heat Recovery Exchanger stands at the forefront of sustainable development initiatives, offering a robust strategy to diminish energy consumption and mitigate carbon emissions on a global scale. These systems epitomise the principle of energy conservation by reutilising waste heat from many sources, thereby curtailing the reliance on fossil fuels and contributing to a reduction in the overall carbon footprint. Such innovative utilisation of waste heat directly aligns with the objectives of sustainable development, which seeks to meet the needs of the present without compromising the ability of future generations to meet their own needs.

The significance of heat-recovery systems in fostering sustainable development extends beyond mere energy efficiency. By capitalising on waste heat, these systems alleviate the pressure on natural ecosystems by reducing the demand for raw energy extraction and processing, which often entail significant environmental degradation. Consequently, this contributes to preserving biodiversity and protecting natural habitats from the adverse effects of conventional energy production methods.

Moreover, heat-recovery systems embody the transition towards more circular economies. These systems transform waste into a valuable resource, thus exemplifying the circular economy principle of minimising waste and maximising resource efficiency. This shift enhances energy resilience and paves the way for more sustainable industrial practices.

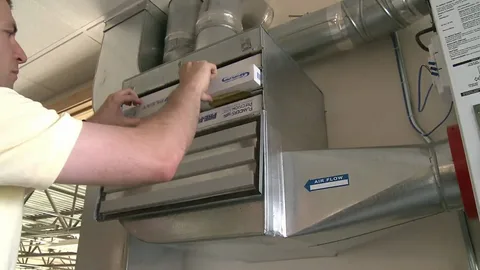

Integrating a Heat-Recovery System into Your Existing Infrastructure

Integrating a heat-recovery system within an existing infrastructure necessitates careful planning and consultation with experts in the field. An initial step involves:

- Conducting a detailed assessment of the structure’s current heating and cooling demands.

- Pinpointing potential sources of waste heat.

- Determining the most suitable variant of a heat-recovery system that aligns with the facility’s specific needs.

This stage is crucial in ensuring that the chosen system can be seamlessly incorporated without necessitating extensive alterations to the existing setup.

Collaboration with professionals who specialise in heat-recovery technologies is indispensable throughout this phase. These experts bring invaluable insight into the selection of appropriate systems, taking into account the unique characteristics of the building and its operational dynamics. Their expertise extends to advising on the optimal positioning of the system to maximise heat capture and efficiency.

Another critical aspect of integration involves evaluating the new system’s compatibility with the current infrastructure. This includes understanding the architectural constraints, the capacity of existing ductwork, and the feasibility of integrating new components without compromising the building’s structural integrity or aesthetic. Considering the regulatory requirements and ensuring the installation complies with all relevant standards and codes is also essential.

Overcoming Common Challenges with Heat Recovery Ventilation Unit

Navigating the intricacies of Heat Recovery Ventilation Unit can sometimes present certain hurdles. These barriers range from the technical complexities associated with system design to the practicalities of maintenance and operation. A prevalent challenge is ensuring the longevity and effectiveness of these systems, which requires a disciplined approach to maintenance. If addressed, such systems are susceptible to fouling and scaling within heat exchangers, which can diminish their efficiency and operational capacity.

Another common area for improvement arises from the system’s complexity. Heat-recovery solutions encompass a variety of technologies and components, each with specific requirements for optimal functionality. This complexity can pose challenges in terms of integration with existing infrastructures, particularly in older buildings where the feasibility of retrofitting needs careful consideration. Additionally, navigating the regulatory landscape to ensure compliance with current standards and codes can be daunting for those who need to become more familiar with the specificities of energy efficiency regulations.

To effectively surmount these challenges, stakeholders are encouraged to engage with professionals specialising in heat-recovery technologies. Such experts can offer guidance on selecting the right system to match a facility’s unique needs, ensuring that it can be integrated seamlessly and operate efficiently within the given constraints. Furthermore, they can provide insights into mitigating the risks of fouling and scaling through design considerations and recommend a maintenance regime tailored to the system’s specificities.

Maximising Efficiency: Tips and Tricks for Maintaining Your Heat-Recovery System

To ensure that a heat-recovery system operates at peak efficiency, meticulous attention to maintenance is imperative. Here are some effective strategies to maintain such systems, designed to optimise their performance and longevity:

Regular Inspection and Cleaning

Components of heat-recovery systems, such as filters and heat exchange surfaces, should be inspected and cleaned regularly to prevent blockages that can reduce efficiency. Dust and debris accumulation impedes airflow and heat transfer, leading to higher energy consumption and reduced output.

System Monitoring

Implement continuous monitoring mechanisms to track the performance of the heat-recovery system. Utilise sensor data and performance metrics to identify any deviations from normal operational parameters, which could indicate potential issues or opportunities for efficiency improvements.

Preventive Maintenance Schedule

Establish a preventive maintenance schedule based on the manufacturer’s recommendations and best practices. This proactive approach helps identify and rectify minor issues before they escalate into significant problems that could impair system functionality and efficiency.

Seal Leaks Promptly

Inspect ductwork and connections regularly for leaks. Even minor leaks can lead to significant energy losses. Ensuring that all components are properly sealed and insulated minimises heat loss and maximises system efficiency.

Professional Audits

Engage with professionals for periodic audits of the heat-recovery system. Expert evaluation can uncover areas for efficiency gains that may not be apparent through routine maintenance checks. These professionals can also provide tailored advice on system upgrades or adjustments to enhance performance.

Employee Training

If applicable, ensure that staff or household members are familiar with the heat-recovery system’s basic operations and maintenance requirements. Educated users can identify potential issues early and operate the system more efficiently.

Upgrade Components

Consider upgrading system components to more efficient versions or adding enhancements recommended by energy efficiency experts. Technology advances rapidly, and newer components can significantly improve performance and energy savings.

Adhering to these tips and tricks ensures that the heat-recovery system remains in optimal condition, delivering on its promise of energy efficiency and sustainability benefits.

Maximising Efficiency: Optimising Your Heat Energy Recovery System

Optimisation of Heat Energy Recovery System is a meticulous process that involves continuous monitoring and strategic adjustments to guarantee the system operates within its highest efficiency parameters. Through diligent analysis of energy consumption patterns, temperature fluctuations, and overall system performance, areas requiring refinement can be identified, presenting opportunities for efficiency enhancement. Engaging with professionals experienced in heat-recovery technologies is instrumental in this optimisation effort. They possess the insights and expertise to recommend and implement modifications that could significantly boost system performance and energy savings.

Optimising a heat-recovery system extends beyond routine maintenance; it entails a proactive approach towards system management. Adjustments may include:

- Fine-tuning the flow rates of heat exchange fluids.

- Recalibrating control systems to match operational demands better.

- Implementing advanced thermal insulation practices to minimise heat loss.

Each adjustment ensures that the system functions at its optimal capacity, thereby maximising energy conservation and reducing operational costs. Furthermore, the optimisation process benefits from a holistic view of the system’s integration within the broader infrastructure. It assesses not just the heat-recovery system in isolation but also its synergies with other building systems to identify comprehensive efficiency strategies.

Improving Indoor Air Quality with Heat-Recovery Systems

Heat-recovery systems extend their utility beyond merely enhancing energy efficiency, playing a pivotal role in advancing indoor air quality. By their very nature, these systems facilitate a reduction in the dependency on mechanical ventilation, which traditionally contributes to the inflow of external pollutants. Heat-recovery systems ensure a continuous supply of purified air by efficiently recycling heat from exhaust air and transferring it to incoming fresh air. This mechanism is particularly advantageous in buildings situated in areas with high levels of outdoor pollution or environments with constrained ventilation possibilities.

Heat recovery and air exchange inherently filter out a significant portion of airborne pollutants, thus contributing to a healthier indoor environment. Occupants benefit from an atmosphere with lower contaminants such as dust, pollen, and other particulate matter. Moreover, improved air quality can have a profound impact on individuals’ well-being, enhancing comfort levels and reducing the risk of health issues associated with poor air quality.

The strategic implementation of heat-recovery systems signifies a step towards achieving greater energy conservation and ensuring superior indoor environmental quality. Through their operation, these systems align with broader objectives of sustainable building design, embodying an integrated approach to energy efficiency and environmental health.

Conclusion

In the landscape of energy management, the prominence of Heat Recovery System is undeniable, presenting a sophisticated solution to energy efficiency and sustainability challenges. Through their innovative reuse of waste heat, these systems stand as a testament to the strides made towards a more sustainable and economically viable future. Exploring their environmental benefits and versatility across various applications underscores the potential for widespread adoption in both commercial and residential sectors. The journey towards integrating these systems into existing infrastructures highlights the importance of professional guidance and the necessity for tailored maintenance strategies to unlock their full potential.

FAQs

What is the typical lifespan of a Heat Recovery System?

The longevity of Heat Recovery System largely depends on the specific type, quality of installation, and adherence to a rigorous maintenance schedule. On average, these systems serve effectively for up to 20 years, with particular components possibly requiring replacement or upgrades over time to maintain optimal performance.

Can heat-recovery systems be retrofitted into older buildings?

Yes, it is feasible to retrofit heat-recovery systems into older structures. However, the complexity and cost of such an undertaking vary depending on the building’s existing infrastructure and installed system type. Professional assessments are crucial to determine the most suitable approach for integration without compromising the property’s architectural integrity.

How much can heat-recovery systems reduce energy costs?

While reducing energy costs associated with implementing heat-recovery systems varies by application, typical installations can lead to significant savings. In some instances, energy expenditure can be reduced by up to 30-50%, depending on the efficiency of the system installed and the pattern of energy usage within the facility.

Are there any government incentives for installing heat-recovery systems?

In many regions, governments offer incentives, including grants, tax rebates, and subsidised loans, to encourage the adoption of energy-efficient technologies such as heat-recovery systems. Potential adopters should consult local energy agencies or authorities for information on available incentives.

Do heat-recovery systems require a lot of maintenance?

Maintenance requirements for heat-recovery systems are relatively modest but essential for ensuring sustained efficiency and longevity. Regular servicing, including cleaning filters, heat exchange components, and periodic checks by professionals, is recommended to prevent performance degradation over time.

| Related Business Listings |

| Contact Directory |

| Local Business Profiles |